News and Innovations

October 2025

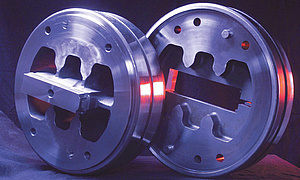

Expansion thanks to reduction?

Expansion and reduction are not mutually exclusive in this case. By retrofitting your machine with our reducing kit, you decrease the cylinder diameter of your abrasive flow machine and thereby expand your processing spectrum. As a result, you are perfectly prepared for both test processing as well as serial production, for small, delicate and large components – all with one machine.

July 2025

You set the goal. We find the way!

Every component is unique – just like our solutions. Whether valve housing, gear part, turbine blade, die or 3D component - every workpiece requires individual surface processing. We are your partner for the abrasive flow process, from analysis to contract machining or implementation of the process at your company. Together we will develop your individual machining solution.

April 2025

Almost as good as new!

Cost-saving general overhaul instead of an expensive new purchase

Have your abrasive flow machines still been in tireless use for many years thanks to their robustness? We offer you a professional general overhaul of your machines (Micro+Hega, Micro Technica, Dynetics or others) so that you can count on reliable production for years to come.

November 2024

Two specialists under one roof

The decision to unite Sampas + SilverCut GmbH and Micro + Hega Surfaces GmbH at a joint location in Kernen-Rommelshausen brings numerous advantages. Both for the two companies and also for our customers.

April 2024

Post-processing of additively manufactured components

With additively manufactured components (rapid prototyping or 3D printing), there is often a need to improve the surface quality. With the help of abrasive flow machining, the surfaces in internal channels and complex component geometries in particular can be processed and excellent results achieved.

November 2023

Spare parts even after years

Are your abrasive flow machines still doing their job safely and tirelessly for many years? Have your cleaning systems also been in use for many years thanks to their robustness? With expert maintenance, older machines will continue to function perfectly and reliably even after decades.

July 2023

Efficient processing of extrusion dies

Extrusion dies must be reworked and optimized by skilled professionals in laborious work by hand. These works increasingly result in higher tool price. The use of MicroStream abrasive flow machining leads to a significant cost reduction while improving the quality of the end product.

April 2023

AFM-Medium streamer – the liquid file

The central tool for the mechanical removal process of Micro Stream abrasive flow machining is the streamer. It is individually adapted to the material to be processed, the component geometry and the desired surface quality. This supports the process decisively, reduces machining times and delivers the best surface qualities.