MicroStream - Abrasive Flow Machining

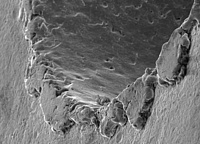

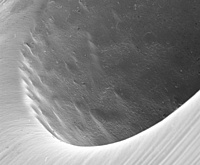

Abrasive flow machining (AFM) is a mechanical removal process. The method is used for producing high-quality surface finishes on internal and external contours, for targeted precision deburring and defined edge rounding or the precise deburring of intersections.

The focus here is on internal channels and complex component geometries. The machining of external geometries is also possible.

Your advantages:

- Reproducible, reliable process

- Consistent quality

- Increased tool service life

- Elimination of manual work

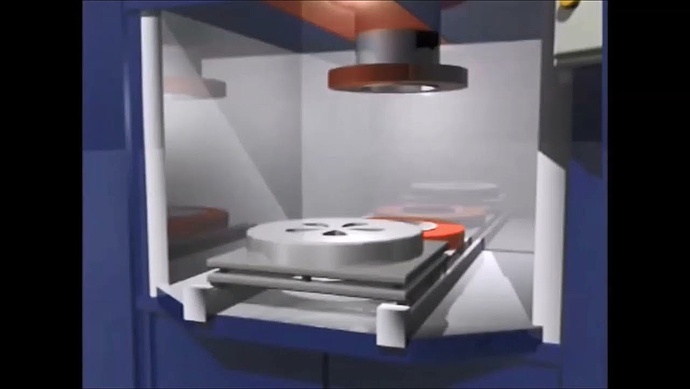

General operating sequence – scheme

General operating sequence – description

Prior to the start of machining, the medium is located in the lower cylinder of the abrasive flow finishing machine. In the workspace between the two pistons, the workpiece, which sits in a specially designed clamping device, is clamped hydraulically between the two cylinders. In general, a separate mounting fixture is required for each component geometry to fix the workpiece in place and to guide the streamer through it.

During the machining process, the medium (streamer) is pushed through the workpiece to be machined and moves from the lower medium cylinder to the upper medium cylinder at a defined pressure or piston speed. A heating/cooling system ensures that the medium’s viscosity remains constant throughout the entire processing period.

Once the processing has been completed, the component is removed, then blown out inside a blast cabin using pressurised air (recirculation of medium residues) before being cleaned in an ultrasound bath as a final step.