Streamer – the AFM Medium

The key for optimal surface qualities, precise deburring and defined edge rounding

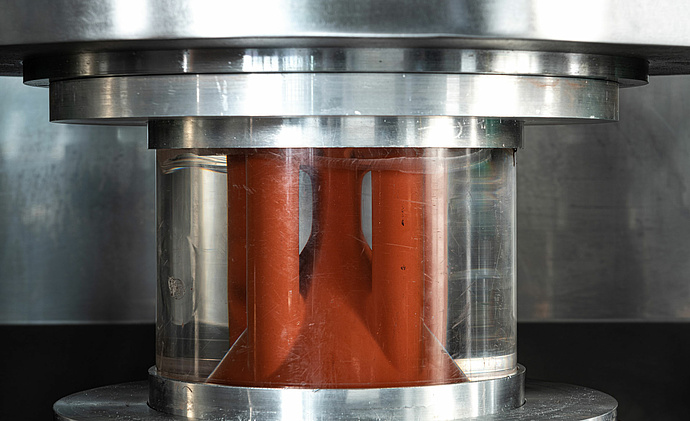

Abrasive flow machining (AFM) focuses on internal channels and complex part geometries. In addition to the machine and the appropriate fixture, the streamer is the most important element for successful abrasive flow machining. The highly viscous mixture firstly must be soft enough in order to flow sufficiently. On the other part its strength must be such that the abrasive grains can be pressed against the surface of the component with sufficient pressure in order to achieve an abrasive effect.

We would be pleased to develop the most efficient abrasive medium formulation for your individual processing task. Contact us.

The streamer, which is individually tailored to your machining task, supports the process decisively:

√ Reliable, reproducible process

√ Reduction of processing times

√ Best surface qualities

√ Reconsistent quality

√ Increased tool service lifes

√ Elimination of handwork

Your benefits:

Customer-specific production of the streamer depending on the individual machining task

Depending on the material and the requirements:

use of silicone carbide, corundum, boron carbide or diamond abrasive grainsMachining of bores and internal cross sections from approx. 0.2 mm to 300 mm

by adapted streamer formulationDifferent viscosities for various applications

Mixtures of several grains possible for optimal results

Upon customer request we manufacture the streamer free from products of animal origin

Processing options:

Processing of complex interior geometries

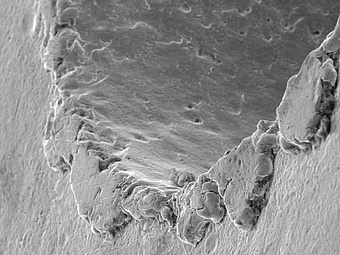

Deburring of hard to reach drill holes, gaps, grooves and edges

Consistently edge rounding

Improvement of surfaces of additively printed components

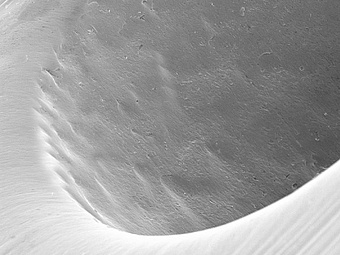

Polishing of milled surfaces, turned or cast components

Removal of martensite layers, e.g. after eroding

Examples of successful processing:

- Automotive Industry (nozzles, valve housings, gear parts)

- Plastics-/ Aluminium Industry (dies)

- Tool- & carbide processing (dies, tablet molds, drawing molds, removal of the erosion layer)

- Medical Engineering (membran, valves, pumps, implants)

- Aerospace Industry (blisks, turbines, guide vanes)

- Textile machinery (thread take-up nozzle, ceramic components)

Everything from a single source

Take advantage of the synergy effects that result from our integration into the Pütz Group! In addition to surface finishing technologies as well as industrial cleaning technologies, we can also offer you the right testing technology to test surfaces and dimensional accuracy.