Reduce costs. Increase quality.

Efficient processing of extrusion dies

The demands on the quality of aluminum profiles are growing constantly. At the same time, the demand for cheaper products – with the same or even better quality – is increasing.

For you, this means optimizing processes and costs.

This requires tools that can withstand higher loads, achieve longer tool lives and offer a high surface quality.

Our solution: with MicroStream Abrasive Flow Machining your dies are polished in the best possible and consistent quality!

Your benefits:

Higher quality of the end product

Huge cost reductions in the whole process

Reproducible results with same quality

Higher service life of tools

Increased extruding volumes

Minimizing the scrap quantity

Suitable for new and used dies

Time saving and quality improvement compared to manual work

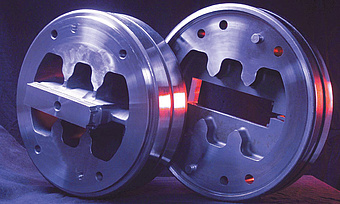

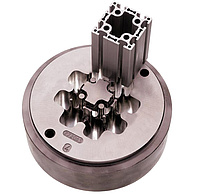

MicroStream Abrasive Flow Machining for extruded profiles with a perfect surface.

The polishing of the dies takes place in the direction of extrusion.

The result: optimum surface roughness values!

The MicroStream Abrasive Flow Machining remove gray layers and small fissures and guarantee identical rough depth values everywhere. According to the processing time, surface values of Ra 0.2 μm and Rz 1 μm can be achieved. Subject to the tool dimensions dies with one strand and multiple strands are processed.

Everything from a single source

Take advantage of the synergy effects that result from our integration into the Pütz Group! In addition to surface finishing technologies as well as industrial cleaning technologies, we can also offer you the right testing technology to test surfaces and dimensional accuracy.