Every component is unique – just like our solutions.

You set the goal. We find the way!

With over 30 years of experience in abrasive flow machining, we use your samples to develop precisely tailored machining processes for the highest surface quality. The process is convincing wherever reproducible and high-quality results are required – especially for internal surfaces and complex component geometries. This is where our strength lies. As an experienced partner, we support you with technical expertise and economic thinking. Together we will develop your perfect solution – efficient, targeted, sustainable.

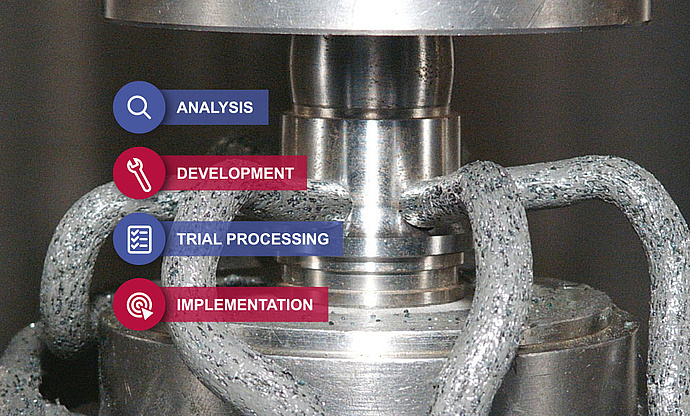

The path to your individual machining solution:

Your benefits at a glance:

In-house fixture construction –

economical, flexible and functionalIn-house streamer production –

individual and variableCost-effective contract machining –

reliable and high quality, short delivery timesIn-house mechanical engineering –

customized to your requirementsSophisticated machine program –

for abrasive flow machining, polishing, rounding and vibratory finishingIndustrial cleaning technology

Individual automation concepts –

in cooperation with Pütz Group companies

Perfectly deburred, precisely rounded, shiny polished surfaces

Our heat exchangers combine a ring and rib design – for maximum cooling and heating performance. The specially developed „waterproof coating” also protects against condensation – for long-lasting and reliable streamer use.

Customised devices – precisely tailored to your workpiece

Each device is individually designed, constructed and manufactured by us – to suit the machining task. It fixes the workpiece, guides the streamer precisely, protects sensitive areas and functionally closes off the machining system.

Pütz Group – a strong association of specialists.

Our network of experts optimizes your production for maximum efficiency.