Affordable upgrades – flexible machining:

Reducing kit for maximum flexibility in surface processing

Our innovative reducing kit for your MicroStream abrasive flow machine gives you significantly more flexibility: Series production, trial machining or special tasks can be carried out with minimal conversion effort and maximum efficiency – without the need for additional expensive new equipment.

Quick conversion: ready for use in just 45 minutes!

Your benefits at a glance:

- Flexible adjustment:

Quick and easy reduction of the existing cylinder diameter - Optimal process control

through easy adjustment of medium and clamping pressure - Extended range of machining operations:

- Series production

- Trial machining without high costs

- small, delicate to large components

- a wide variety of diameters - Efficient use of materials: l

ower consumption of high-quality streamers - Can be integrated retrospectively

Optional extensions:

Unlock the full potential of your abrasive flow machine

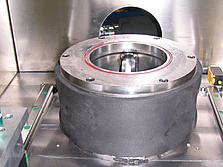

![[Translate to Englisch:] Reduzierkits [Translate to Englisch:] Reduzierkits](/fileadmin/_processed_/d/6/csm_okt-25-reuzierkits_5c3931712e.jpg)

Our reducing kits

are available for your MicroStream abrasive flow machine in various diameters from 50 to 200 mm. We supply special sizes on request.

![[Translate to Englisch:] Micro + Hega Surfaces – Wärmetauscher [Translate to Englisch:] Micro + Hega Surfaces – Wärmetauscher](/fileadmin/_processed_/2/2/csm_okt-25-waermetauscher_bdbad5041b.jpg)

Our heat exchangers

combine ring and rib design to ensure maximum cooling and heating performance. The specially developed „waterproof coating” provides reliable protection against condensation, ensuring particularly long-lasting and safe streamer use.

Pütz Group – a strong association of specialists.

Our network of experts optimizes your production for maximum efficiency.