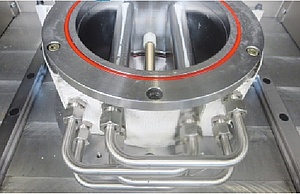

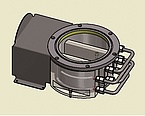

The new heating/cooling system with anti-condensation coating

Consistent temperatures for your grinding media

A new heat exchanger

- Significantly improved cooling and heat conduction thanks to a combined ring and rib design

- A special submarine coating further protects the Streamer against the formation of condensation

A new heating/cooling unit

- Improved technical applications thanks to the combination of gas and glycol

Your benefit:

+ Constant abrasion performance

+ Reproducible processing results thanks to the consistent processing quality

+ A long service life for the abrasive media

The operation of the heat exchanger:

The temperature is influenced via the heat exchanger, which sits on the lower medium cylinder. The process-dependent temperature of the grinding medium is preset and stored via the PLC. A temperature sensor transmits the values and the heat exchanger regulates the temperature via the PLC.

EVERYTHING FROM A SINGLE SOURCE

Thanks to our integration into the PÜTZ GROUP and the resulting synergy effects we are able to offer you not just deburring and surface technologies but also the appropriate testing technology to test surfaces as well as for dimensional accuracy.