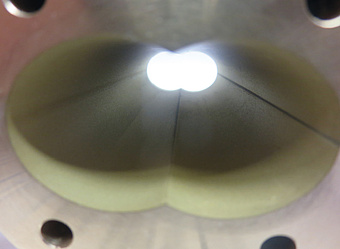

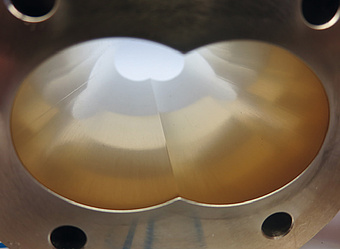

The perfect solution for optimal surface quality and edge rounding:

MicroStream-Abrasive Flow Machining

MicroStream-Abrasive Flow Machining is a mechanical finishing process, in which Streamer is one of the key components for successful processing. At Micro + Hega Surfaces this is specially adapted to the component to be processed (material, geometry, required surface quality etc.) and manufactured to customer specifications.

The highly viscous mixture must fulfil two important aspects: firstly it must be soft enough in order to flow sufficiently; secondly its strength must be such that the abrasive grains can be pressed against the surface of the component with sufficient pressure in order to achieve an abrasive effect.

We would be pleased to develop the most efficient abrasive medium formulation for your individual processing task. Contact us.

√ Creates high quality surface qualities on interior and exterior contours

√ Targeted precision deburring of intersections

√ Defined edge rounding with reproduceable work results

Your benefits:

- Customer-specific production of the Streamer

Depending on the material and the requirements: use of silicone carbide, corundum, boron carbide or diamond abrasive grains - Mixtures of several grains possible For optimal results

- Processing of minimal to large diameters Depending on the grain size used

- Available in different viscosities Depending on application

Application examples:

- Processing complex, intricate and complicated interior geometries

- Deburring of hard to reach drill holes, gaps, grooves and edges

- Consistently and evenly rounded edges, e.g. on tooth flanks and edges on gears

- The improvement of surfaces, including additively printed components (3D-components)

- Polishing of milled surfaces, turned or cast components

- Removal of martensite layers, e.g. after eroding

Your partner in contract manufacturing

If the use of your own machine for the improvement of edges and surfaces is not currently worthwhile for you or if you would like to convince yourself of the quality of the processing over a longer period, then we can process your workpieces in our contract manufacturing department in Freiberg am Neckar (near Ludwigsburg) at a good price.

We would be pleased to carry out an initial feasibility analysis for your individual component in order to find the most efficient and suitable process for your deburring or surface problem.

EVERYTHING FROM A SINGLE SOURCE

Thanks to our integration into the PÜTZ GROUP and the resulting synergy effects we are able to offer you not just deburring and surface technologies but also the appropriate testing technology to test surfaces as well as for dimensional accuracy.