Greater flexibility in surface processing

MicroStream® abrasive flow machine adapts to your needs!

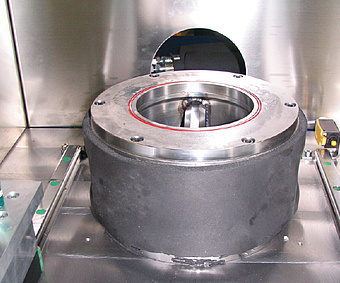

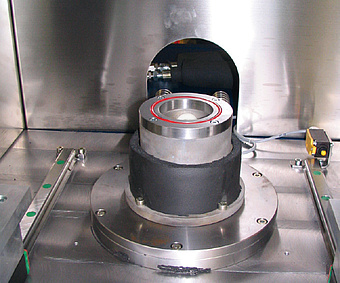

Our MicroStream® abrasive flow machine can be quickly adapted to individual customer requirements thanks to optional extensions. By using our reducing kit, you can expand your processing spectrum – without the use of additional, expensive machines. Apart from serial production, other operations, for example test processing, become possible without major modifications and costs.

- Reducing Kit Available in various diameters (50 - 250 mm), special sizes are available on request

- Optional: Including heat exchanger

- Software customisation for adjusting to different medium and clamping pressures

Your benefits:

Rapid reduction of the existing cylinder diameter Conversion time of approximately 45 minutes

Easy adjustment of medium and clamping pressures

Wider machining spectrum:

- Serial production

- Small, delicate to large components

- Small to large machining diameters

- Test processingCost savings thanks to lower consumption when using high-quality and expensive streamers

Optional: Heat exchangers for constant material removal rates, reproducible processing results, a long service life of the abrasive media

Advantages of MicroStream® abrasive flow machining (AFM):

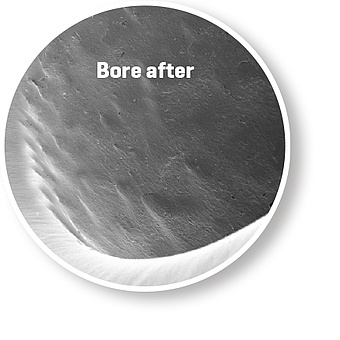

- Highest precision

- Optimal quality

- Enormous time savings compared to manual deburring processes

- Irrespective of geometric shapes

Processing options:

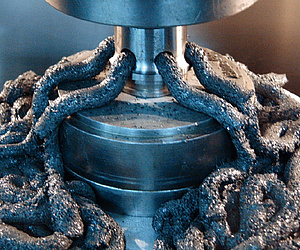

- Grinding of internal bore surfaces

- Deburring of hard-to-reach bores as well as crevices / grooves and edges (several bores simultaneously)

- Consistent and even rounding of edges, e.g. tooth flanks and edges on gears

- Polishing of milled, turned or cast components

- Processing of additively manufactured components / 3D components

- Removal of martensite layers, for example after eroding

EVERYTHING FROM A SINGLE SOURCE

Thanks to our integration into the PÜTZ GROUP and the resulting synergy effects we are able to offer you not just deburring and surface technologies but also the appropriate testing technology to test surfaces as well as for dimensional accuracy.