Optimization of medium piston in the grinding process of inside surfaces

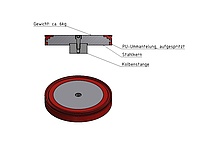

The new modular medium piston of MICRO SURFACES will minimize the exchange of spare parts in the future.

In case of wear of the sealing edge, the exchange of only the piston seal and - after an extended runtime - the guide band is required.

You can benefit from the advantages of:

+ Procurement of wear parts 300% cheaper in the future

+ Shorter delivery terms from 6 weeks to 2 week

+ Eco-friendly due to reduced costs of materials

+ More assembly-friendly due to reduced piston weight

Task of the medium piston:

The medium piston has the task to press the grinding paste in the medium container through the workpiece to be processed.

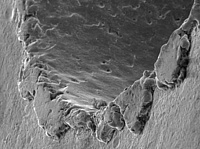

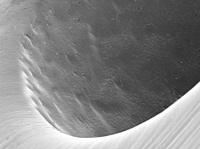

For this purpose, it must be located sufficiently nearby the medium container wall in order to avoid the occurrence of grinding paste behind the medium piston. The grinding paste contains abrasive particles, leading to the wear of the sealing edge of the medium piston.

Switching to NEW is possible at any time!