Optimization of medium piston in the grinding process of inside surfaces

Task of the medium piston:

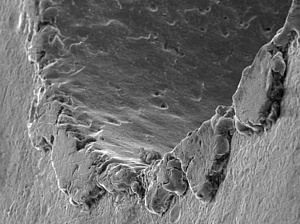

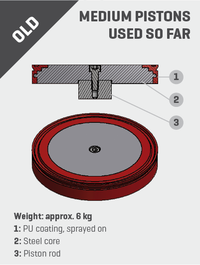

The medium piston has the task to press the grinding paste in the medium container through the work-piece to be processed. For this purpose, it must be located sufficiently nearby the medium container wall in order to avoid the occurrence of grinding paste behind the medium piston. The grinding paste contains abrasive particles, leading to the wear of the sealing edge of the medium piston.

Your benefit:

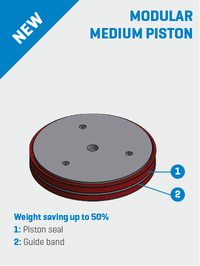

+ Procurement of wear parts 300% cheaper in the future

+ Shorter delivery terms from 6 weeks to 2 weeks

+ Eco-friendly due to reduced costs of materials

+ More assembly-friendly due to reduced piston weight

Switching to NEW is possible at any time!

EVERYTHING FROM A SINGLE SOURCE

Thanks to our integration into the PÜTZ GROUP and the resulting synergy effects we are able to offer you not just deburring and surface technologies but also the appropriate testing technology to test surfaces as well as for dimensional accuracy.